“这座桥仍然站着?”

That was the initial reaction of Aaron Stover, Michael Baker International’s vice president and regional bridge practice lead, as he first studied images of a fractured tie beam that forced the May 11 emergency shutdown of the I-40/Hernando de Soto Bridge between Tennessee and Arkansas. Discovered earlier in the day during MBI’s routine above-deck inspection, the fracture on the bridge’s eastbound span affected nearly half the cross-section of a 26-in. by 33-in. welded girder supporting one of the 50-year-old structure’s 900-ft-long, 100-ft-high arched navigation spans across the Mississippi River.

Though component fractures have occurred on older structures, Frank Russo, MBI’s national bridge technical director, says the de Soto Bridge crack was nevertheless puzzling. The tie beam’s .5-in.-thick top flange plate and outer 1-3/8-in.-thick web plate were totally severed, with the fracture extending across nearly half of the bottom flange plate. Additionally, 9 ft of the weld connecting the inside web with the upper flange had separated as well.

.jpg)

Shortly after the fracture was discovered, the 900-ft-long bridge spans were closed and inspections began. Here, workers are taking part in the early stages of phase 2 repair work.

Photo courtesy Michael Baker International

“通常,当类似的事情破裂时,您会发现它完全破碎,” Russo说。“这位成员没有完全破裂,这是非常了不起的。”

Though the fissure’s cause and characteristics remain under investigation, two things were clear as the bridge was immediately closed to traffic—its condition needed to be thoroughly assessed in the event there was additional damage, and a repair strategy needed to be developed as quickly as possible.

5月11日发现的裂缝导致桥梁立即紧急关闭。

Photo courtesy Michael Baker International

尽管骨折的方面存在非凡的方面,但在对De Soto Bridge和彼此之间进行评估的团队中,团队的熟悉程度很高。阿肯色州和田纳西州的运输部门长期以来对该结构负责,Ardot负责监督检查和TDOT处理维护。MBI将领导响应的航空检查和设计工作,与HNTB一样,与HNTB一起工作,该机构对两种绑定架构的绑定跨度进行了全面检查。联邦公路管理局的专家也参与其中。

检查员获得了骨折的特写视图。

Photo courtesy Michael Baker International

“这位成员没有完全破裂,这是非常了不起的。”

- 迈克尔·贝克国际(Michael Baker International)国家桥技术总监Frank Russo

Ardot发言人戴夫·帕克(Dave Parker)表示:“这为我们提供了结构性工程专业知识和资源的深度工作台,可以在很短的时间内进行大量的分析和设计,并具有很高的可靠性和准确性。”

The team also had technology on its side, with drone video combining with physical inspections using rope-access techniques to expedite the condition assessment. Drones also allowed the physical inspection of the fracture to be streamed in real time to the office-based design team.

“We could see what the inspector was doing and ask to check out additional aspects, which helped us start planning multiple steps ahead,” says MBI bridge technical director Jason Stith. “It was quite incredible to get that information during a two-hour conference call rather than having to go back and forth over several days.”

This image shows the view when inspectors first discovered the crack.

照片由田纳西州运输部提供

The emergency situation for this vital connection between Tennessee and Arkansas required work to progress on a 24/7 basis.

Photo courtesy Kiewit

多路计划

Though no additional damage was found on the bridge, in-depth inspections indicated that the structural load at the fracture had been shed to the remaining web and flange sections, putting those components under exceptional stress.

“We needed to understand that better before we started yanking around on the bridge, trying to move things back to where they were,” Stover says.

As the team began concurrent design efforts to stabilize the structure and devise a permanent repair, TDOT implemented an emergency construction manager/general contractor procurement that agency commissioner Clay Bright says had the capability “to get involved in the difficult, challenging and at the time, still unknown final repair design.”

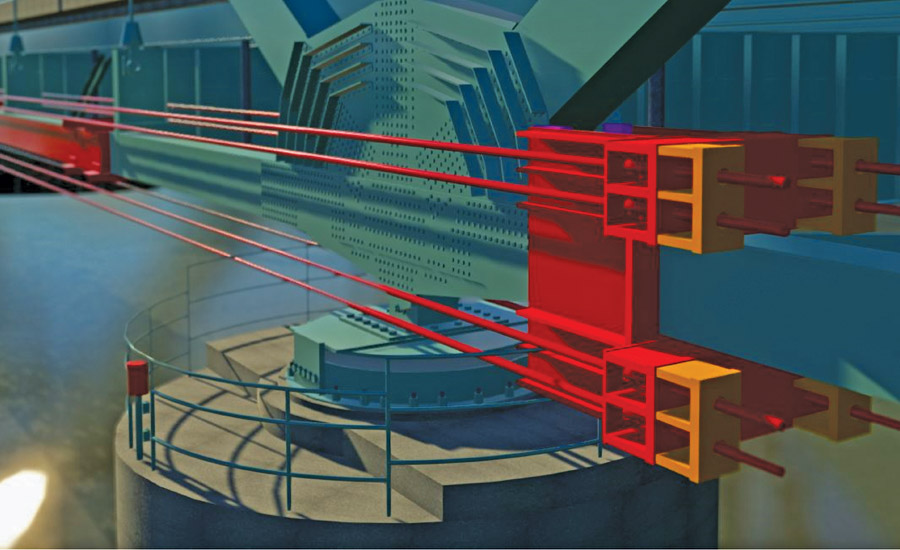

在结构修复期间使用的2阶段后张紧方案的概念渲染。

提供礼貌迈克尔·贝克国际

On the afternoon of May 17, less than two hours after TDOT had selected Kiewit for the project, operations vice president and area manager Chris Frieberg and other firm representatives were discussing stabilization and repair alternatives with the design team.

“We worked through risks associated with different design options and the best way to mitigate them, as well as material availability and fabrication lead time,” Frieberg says. He adds that the solution had to be one the design team could stand behind and his team could build safely.

提供礼貌迈克尔·贝克国际

他补充说:“而且必须是永久的,这样点可以保证在未来几年内拥有安全的结构。”

The resulting two-phase strategy called for first stabilizing the fracture area with a “splint” of steel plating that would add redundancy to structure. Because the girder was slightly twisted and warped, the plates would be offset to prevent placing any new stress on the area.

尽管TDOT最初设想了驳船的维修工作,但设计团队的加载分析表明,可以从桥甲板安全地访问裂缝区域。

弗里伯格说:“尽管我们确实必须将人员和设备保持在最低限度,但这为我们提供了更加控制的环境。”

到第一周结束时,基维特(Kiewit)组装了一个100平方英尺的悬挂平台,以在肯塔基州鲍林格林(Bowling Green)的Stupp Bridge Co.加速制造的基础上安装了30,000磅的HPS70W结构钢板中的第一个。

Over the next four and a half days, crews used chain and air hoists to lift the plates into place, where they were secured with nearly 450 temporary bolts. Frieberg says the work involved some lead paint considerations and confined space protocols when working inside the tie beam but required no additional measures for COVID-19.

The ability to use drones to inspect the damaged bridge aided the project team.

From Stopgap to Structurally Sound

On May 14, just three days after discovery of the fracture, the de Soto bridge was deemed sufficiently stabilized and safe enough for TDOT to reopen the underlying river channel to barge traffic and then transition to the next repair phase. A 150-ft-long section of tie girder encompassing the fracture area would be beefed up with 108,000 lb of additional redundancy plating, with eight 3-in.-dia, high-strength, post-tensioning rods installed alongside the beam to transfer more than 1.2 million lb of tension to the composite section.

The supplemental post-tensioning also allowed workers to remove fractured flange sections for analysis.

“If the entire tie decided to break, which is very unlikely, it has a completely redundant element on the outside that can carry the load,” Russo says.

Frieberg says this strategy required an even higher level of coordination and analysis given that the precision fabrication of specialized post-tensioning components and weldments and additional strengthening plates had to be synced with mobilizing specialty subcontractors and addressing other logistics needs.

他说:“我们有三个关键的道路同时运行,而舞蹈的艺术使它们全部保持一致。”“这三个都融合了,因此当设计被签名并密封时,材料制造正在进行中。”

到7月3日,骨折位置的最后一个盘子已螺栓固定在适当的位置。但是,在宣布桥梁完全恢复之前,还有一个更重要的步骤要完成。在最初的条件检查中,HNTB对TIE Girders的500个焊缝进行了非破坏性阶段阵列超声测试,以确定是否形成了类似的裂纹或在某些条件下可能形成。发现有17个焊缝具有异常,在接下来的三周内,Kiewit镀了,总计78,000磅的钢,以提供额外的冗余。另有29个焊接缺陷被磨碎或核心。

“必须是永久的,以便可以确保这些点可以在未来几年内拥有安全的结构。”

—Chris Frieberg, Operations Vice President, Kiewit

另一轮的检查后,德索托Bridge’s eastbound lanes were reopened to traffic on July 31, followed two days later by the westbound lanes. That completed an 83-day, 24/7 marathon that was remarkably free of weather interruptions. Costs for the routine and specialized inspections and repairs, currently estimated at $10 million, will be shared by both DOTs.

这项努力还得出结论,Ardot的Parker认为是一个平行的成功故事,也可以将De Soto Bridge的40,000辆汽车转移到其他过境点上,尤其是附近的72岁的桁架桥,该桥梁在河上带I-55。

帕克(Parker)认为,该团队对拥堵救济策略的合作集思广益,以帮助将I-55桥的最初长达一个小时的高峰小时备份减少一半以上,并减少到当地道路上的释放交通。这两个点都加强了服务,以最大程度地减少关闭车道事件的影响。TDOT的明亮指出,驾车者对I-55桥安全的最初担忧是通过紧急检查和“健壮结构”的性能缓解的,而De Soto桥则无法使用。

“The only issue was a pavement failure in one lane that was quickly addressed during a weekend temporary lane closure,” Bright says, adding that the bridge is currently undergoing its scheduled biannual inspection. “Any new issues will be addressed along with other maintenance work next spring.

同时,裂缝的绑带梁部分在伊利诺伊州诺斯布鲁克的Wiss Janney Elstner的法医实验室进行,经过冶金和其他测试,以完全了解导致裂缝的因素。帕克说,该调查的结果计划由秋季进行,将有助于点确定该结构是否需要在定期安排的检查和维护上进行更多关注。在桥梁重新开放之前安装的太阳能应变量表监测系统也保持运行。

团队成员认为,已经可以肯定的是,在将潜在的灾难变成成功故事中,团队范围内的重要角色是重要的。

“If you listened into our daily calls, you wouldn’t have been able to tell who was DOT, who was designer and who was the contractor,” Frieberg says. “Going through the process, we were very well integrated and very open-minded. That was the biggest contributor with coming up with a design solution that could be implemented quickly and safely.”

Questions Remain in Inspection Oversight Controversy

Within hours of the discovery of the de Soto Bridge tie girder, images and video emerged suggesting that the fissure had been months, perhaps even years, in the making despite having been unreported in at least two ARDOT-led annual fracture-critical inspections. Following an internal investigation launched immediately after the closure, ARDOT fired Monty Frazier, a 15-year employee who had led the 2019 and 2020 de Soto Bridge inspections. In addition, the Federal Highway Administration launched an assessment and compliance review of ARDOT’s bridge inspection program, with the results expected by the end of September.

Frazier’s reported assertion that the mobile under-bridge inspection platforms were unsafe to use was countered by the agency’s heavy bridge maintenance staff (HBMS), which, according to an ARDOT interim after-action report, verified that the equipment was stable and provided adequate access to perform hands-on inspection at the fracture location. Nine other fracture structures inspected by Frazier were reexamined and found to be safe.

此后,弗雷泽(Frazier)承认缺少骨折是他的错误,但他坚持认为他不仅要责怪。弗雷泽(Frazier)在接受《每日孟菲亚报》(Daily Memphian)报纸的采访时说,他指出,据称其可追溯至2014年的照片中的爆发事件证明了其他检查员也忽略了这种情况。“If there are that many people who missed the crack over all that time,” Frazier told the reporter, “it’s a problem with the way we inspect the bridge, not just the one guy who happened to be on the paperwork the last time we missed it.”

ARDOT has not verified the validity of the photos and declined to comment on the story. Meanwhile, multiple investigations are underway, including an agency-requested probe by the U.S. Dept. of Transportation’s Office of Inspector General as to whether Frazier’s alleged negligence constitutes a criminal action. A parallel internal investigation by ARDOT’s human resources department is proceeding as well.

In July, ARDOT boosted its historic bridge maintenance system budget by nearly $3 million, providing funding for consultants that will help the agency identify new technologies, improve quality assurance and quality control and improve inspector training.