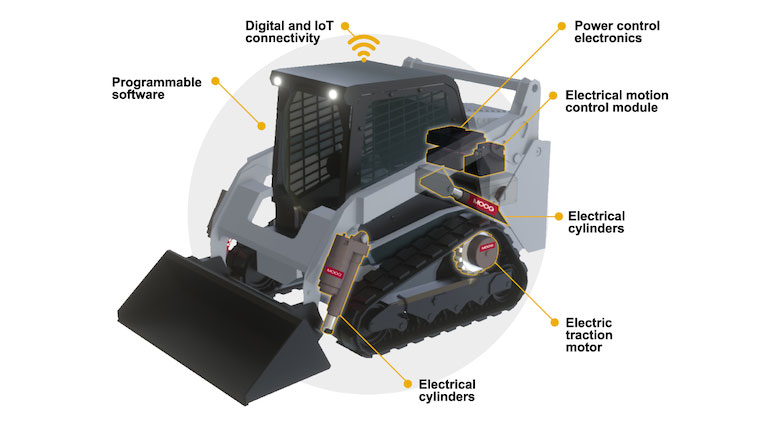

Bobcat Co. turned some heads at the Consumer Electronics Show in January by unveiling the T7X, the company's new all-electric compact track loader that ditches not only the diesel engine but also the entire hydraulic system. While many equipment manufacturers have made electric-concept machines as one-off efforts, Bobcat sees electrification as a broader shift for the industry.

Developed in cooperation with electric vehicle-maker Moog Construction, the T7X is designed to leapfrog some electrification efforts underway in the construction equipment sector, according to Joel Honeyman, Bobcat vice president of global innovation.

“This was two leaps of technology,” he explains. “We not only added the battery, but we’ve added other levels of electronic controls.”

用电动执行器电动机代替紧凑型轨道装载机的传统液压功能提供了与普通机器不同的功率曲线,但霍尼曼(Honeyman)表示这是漫长的旅程的结果。Bobcat North America在2019年开发了一个原型电气紧凑型轨道装载机,但不断完善它以使其成为今天的位置。

“My lead engineer came up one day and said there are companies that do electric actuation,” recalls Honeyman. “We know what hydraulics do, been there forever. But if we go full electric, there are other inherent advantages.”

With the hydraulics replaced, the TX7 has reduced vibration compared to conventional models, and like other electric vehicles, is much quieter during operation. The electric actuators also behave differently than hydraulics, so operators will have to get used to it, says Honeyman. “Once you activate it on the joysticks, that machine will go—you’ve got full torque when starting at zero speed and zero rpm,” he says.

图片由山猫公司提供。

T7X还设置了“野兽模式”的设置,可按需使用全功率和扭矩,但霍尼曼说,它只能在某些手臂和桶位置工作,以防止损坏机器。实际上,电子控件能够在操作过程中监视抽签,并防止操作员意外损坏机器。

“Say that you're rolling back the bucket and a rock is caught in the actuator,” Honeyman says. “With hydraulics you can’t see it and could damage the machine. [With the T7X] we can sense it and have the motors back off.”

他补充说,让机器积极避免损坏可以延长其寿命并避免昂贵的维修。

易于操作

操作也进行了简化。消除the diesel engine means no diesel refueling, while eliminating the hydraulic system means no hydraulic fluid to top off. While there are ecological benefits to a zero-emission machine, going fully electric also opens the T7X and other equipment up to easier automation, according to Joe Alfieri, general manager at Moog Construction.

“Once you have an electric machine, it becomes very controllable, like a robot,” he says. “You can load software to have it do things at that point. [Electrification] enables higher levels of automation.”

The T7X is built to roughly the same form factor as Bobcat’s T76 conventional compact track loader, although the electric model is about 1,000 lb heavier. It can be charged from standard EV-charging ports and will fully charge overnight. The current version is capable of four hours of continuous runtime, with an eco mode to save power.

Because it’s all batteries and electric motors, the idle power consumption is very low, points out Honeyman. “As soon as you let off the joysticks, it is not consuming energy. It’s not running at idle like a diesel machine,” he says. “A lot of customers forget that.”

Bobcat will make the initial group of T7X electric compact track loaders available through Sunbelt Rentals later this year. These initial machines run at a cost nearly three times that of a traditional model—at more than $200,000 each—but Honeyman says the price is likely to drop as Bobcat expands production of electric machines.